Liquid Cold Plates

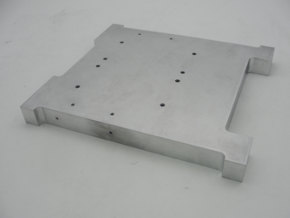

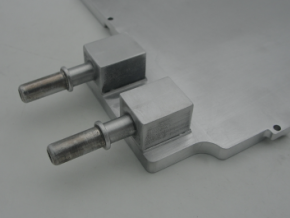

Liquid cold plates provide localised cooling of power electronics through transfer of heat into the liquid.

They are designed such that the flow of liquid through them moves close to the heat dissipating components removing the heat and taking it back to a chiller or liquid to air heat exchanger.

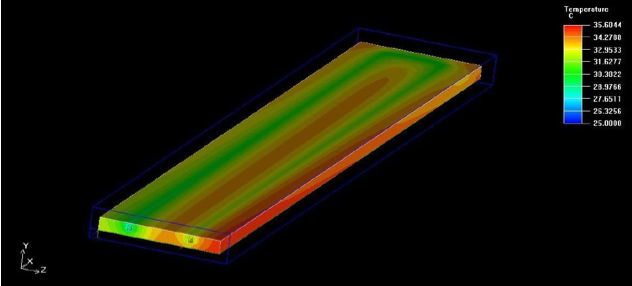

We can provide thermal simulation support to optimise the thermal solution. We use thermal design software packages such as Icepak, Flotherm and Qfin. By integrating theory and practice our experienced engineers can provide solutions optimised for performance weigh and cost.

To help us with your design please complete the checklist below.