Heat Pipes

cTech Heatpipe Thermal Solutions: A Heatpipe is a “two phase” heat transfer mechanism with extremely high “effective” thermal conductivity. A thin walled pipe with an internal wick structure allows boiling and condensing to occur within the pipe resulting in heat transfer from the hot end to the cooled end. Small volumes of liquid evaporate at the hot end, even at low temperatures due to the vacuum inside the pipe, and condense on reaching the cooled end, giving up its latent heat. The condensed liquid then wicks it’s way back to the hot end by capillary action and/or gravity and the cycle repeats.

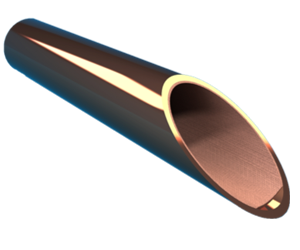

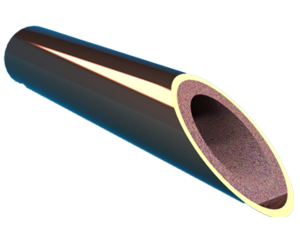

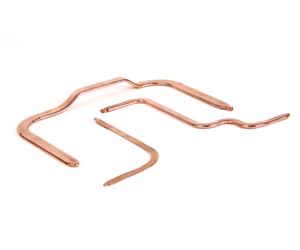

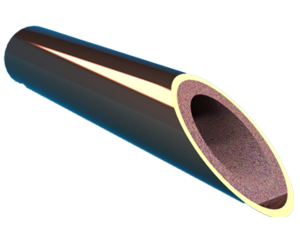

Heat pipes are typically copper and the “working fluid” is usually water. They start as round pipes of varying diameters and can be bent or flattened or both.

- Sintered wick pipes.

- Very high capillary power.

- Works against gravity

- Mesh wick

- High power for a given diameter pipe,

- Needs gravity